History

Mikron Tool, a success story

The origins

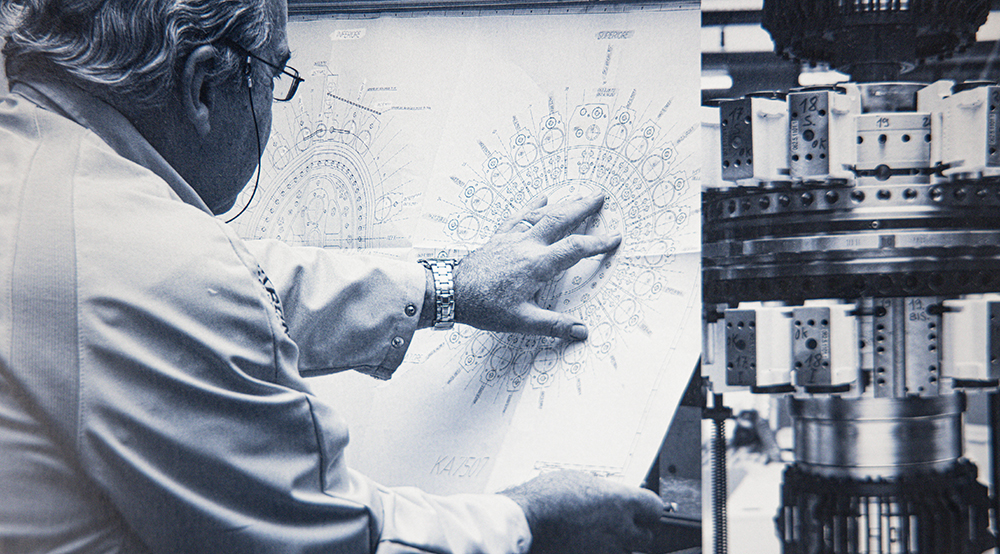

The emergence of Mikron Tool is closely linked to the history of the Transfer Machine manufacturer Mikron SA Agno. Based on a decades long experience as a supplier of tooling for Rotary Transfer Machines, the still young company can look back on a long tradition.

In 1908, the watchmaker Karl Lüthy founded the machinery factory Mikron AG in Biel, taking over the mechanical workshops of Henri Hauser with 35 employees.

In 1953, Sauro Albertini and Guido Bertoglio started the Albe machinery plant specializing in the development and construction of Rotary Transfer Machines for the production of ballpoint pen tips. They gradually started also in-house production of special cutting tools for the Transfer Machines they built.

The birth of Mikron Tool SA Agno and the CrazyDrill revolution

In 1986, Albe was taken over by the Mikron Group and renamed Mikron SA Agno. From then on the in-house capability to produce their own tungsten carbide drill bits became more and more important. The emphasis was on special tools with high life expectancy and precision which are crucial in making sophisticated Rotary Transfer Machines reliable and efficient.

In 1998, Mikron Tool SA Agno was founded as a "spin-off" of the former in-house Cutting Tools department of Mikron SA Agno. It started with a team of 25 people. While supplying best drill bits for Mikron machines they also gradually acquired a reputation as a quality supplier of solid carbide tools in small to midrange sizes.

In 1999, Mikron Tool launches with the industry drill CrazyDrill Steel, the first standardized product family and thus the fastest and best small drill bit for steel in the world. The name stands for the "crazy" cutting speeds and feed rates, for the longest tool life and process reliability. Up to 20 times faster drilling compared to the standard drills available on the market is a reality. Soon other “crazy” products followed. The standardized twist drill grinding belongs now again to everyday life.

Mikron Tool expansion, innovation and global recognition

In 2000, Mikron Tool obtains ISO 14001 certification.

In 2002, the CrazyLine expands by another product, the pilot drill CrazyDrill Pilot, a perfect extension of the already existing families. In the same year, the company obtains the ISO 9001 certification for its quality management.

In 2003, Mikron Tool Rottweil comes into existence as a base for the sale, but above all for the regrinding of Mikron Tool tools in the European region. Special tools are soon manufactured here too.

In 2004, CrazyDrill Cool expands the product range and as a result also small metal work drills with internal cooling are available from stock.

In 2005, Mikron Tool sets up an inventory in the USA and creates a sales organization based on a network of representatives and local distributors.

In 2006, SQS-Qualification [SQS: Swiss Association for Quality and Management Systems] OHSAS 18001 for safety acknowledged the highest quality standard of Mikron Tool.

In 2007, a new micro drill line was initiated: MiquDrill stands for Mikron quality and addresses above all customers with small production series.

In 2008, the branch in Rottweil (DE) moves to a newly built facility and thus expands further the production capacity.

In 2009, Mikron Tool enters with the CrazyMill product line in the milling operations area, for the time being with a series of deburring cutters for all possible processing operations (such as deburring rear side of bores starting at 0.4 mm (.016")).

Closer to Customers in Asia

In 2012, Mikron Tool decides to offer local technical support also in Asia. Now the customers are served directly from Shanghai.

Award-Winning: Innovations in Drilling and Milling

In November, the innovative strategy was rewarded with the Prodex Award, a Swiss prize for the most innovative products in the manufacturing and production areas. Mikron Tool was awarded second place for the development of CrazyDrill Flex, a revolutionary, flexible micro drill.

In 2013, Mikron Tool sets a milestone in milling technology with the launch of the CrazyMill Cool micro cutter specially designed for stainless steels, titanium, Cr-Co alloys and superalloys. With this, Mikron Tool makes a quantum leap in the milling of difficult materials in the small diameter range with performance of up to 20 times higher than it is possible at present. Also this product is bestowed with the Prodex Award: first place in 2014!

Award: From Innovation to Industry Leadership

In 2014, Mikron Tool concentrates on the development of the CrazyDrill SST-Inox micro drill entering resolutely the field of difficult to machine materials in smallest dimensions.

In 2016, a new Inox drill, CrazyDrill Cool SST-Inox, is arriving with a revolutionary cooling system. Cooling channels with a drop-shaped cross-section bring up to 4 times more coolant up to the drill tip.

In 2018, Mikron Tool becomes an independent division within the Mikron Group, an important step in strengthening the tool business.

In 2019, Mikron Tool receives the Prodex Award for "Best Performance Company," a prize awarded by an independent jury at the Prodex Industrial Exhibition in Basel.

Expanding Precision Tool Solutions through DMQP Partnership

Mikron Tool becomes a new DMQP partner (DMG MORI Qualified Product), expanding the portfolio in the segment of precision cutting tools for hard to machine materials for the largest worldwide manufacturer of machine tools. This cooperation is officially sealed on the 50th year's celebration (June 13th) of DMG MORI Switzerland.

Building for the future, innovating for medicine

Construction of a new production building in Rottweil. The groundbreaking ceremony takes place on July 16th in presence of all personnel and members of the Mikron Group, as well as representatives from the city of Rottweil and the building contractor. In November, also in Agno starts the work for the enlargement of the production area.

Mikron Tool held its inaugural Medical Day at the Technology Center, inviting 25 users for exciting talks on all things related to medical technology. The event focused primarily on significantly reducing machining times for medical components.

In 2020, Mikron Tool unveiled an innovative concept for producing Torx® sockets on medical screws made from titanium and stainless steel. Its revolutionary turnkey solution, Hexalobe, marked another significant step towards establishing themselves as a cutting-edge tool manufacturer for medical technology.

Mikron Tool also put a new production facility into service at the Rottweil Germany location.

A Full Immersion into MedTech Innovation

After the first wave of the pandemic, Mikron Tool held another live event in Agno in October. Jointly organized by DMG MORI and Mikron Tool, it was a 'full immersion' day for all things MedTech.

From Crazy Tools to Crazy Services

In 2021, Mikron Tool launched tools with diameters in fractional inches to embrace US customary units. The United States is a leading nation in many high-tech industries, such as aerospace, where the imperial measurement system is more widely used.

To further consolidate its position, Mikron's Board of Directors decided to merge their four Swiss subsidiaries into a new company, Mikron Switzerland AG. Mikron Tool was renamed as Mikron Switzerland AG, Division Tool.

It also added a new corner radius mill to its successful CrazyMill Cool P&S product line.

In 2022, Mikron Tool launched its new streamlined, informative, and entertaining YouTube channel.

It also introduced its engineering services worldwide, transforming the company into a strategic partner for customers.

Growth supported by new facility and sustainability

In November, Mikron Tool officially opened its new production facilities for Mikron Switzerland AG, Tool Division. This new building has an additional 1000 square meters of production space and a state-of-the-art mixing plant for heat recovery from production, eliminating the use of fossil fuels.

It did not stop there. The ageing refrigeration system was also replaced as part of the new construction. Thanks to this renewal, 350,000 kWh of electricity are saved annually.

Passing the Torch: Guiding Mikron Tool into the Future

The retiring head of Mikron Tool, Markus Schnyder, handed over the reins of the division to his long-time partner, Elio Lupica, at a fitting farewell party.

Award: Titanium drilling and micro milling

In November, Mikron Tool won second place at the SMM Award with its 'divine' CrazyDrill Cool Titanium drill series, marking their fourth innovation award in the last 10 years.

In 2023, Mikron Tool presented its latest innovation, the smallest milling cutter in the world, CrazyMill Cool Micro. It is the first milling cutter with material-specific cutting-edge geometries and integrated cooling, allowing for high-performance milling of hard and difficult-to-machine materials in micro-production.

25 years and still “crazy” – Mikron Tool celebrates! With 30 employees, Mikron Tool began writing its success story twenty-five years ago. Today, 250 people on three continents belong to the Mikron Tool family.

Installation of new PVD Coating Plant

In 2024, the production in Agno is expanded to include a PVD coating plant, which is scheduled to go into operation in January 2025. By coating most of our tools in-house, we take complete control of the entire tool production process: from machining the carbides and predefining the geometries to grinding, coating, and pre- and post-processing.

In summer, there are two break-ins at Mikron Tool Eurostock in Rottweil. The first time, the thieves manage to steal numerous tools, but the second time they are discovered in time and the damage is minimal. Thanks to the great commitment of the entire team, the warehouse can be quickly restored without affecting customer service.

At the AMB in Stuttgart, Mikron Tool presents a new high-performance drill and two new high-performance milling cutters: CrazyDrill Titanium TN / TK, specially developed for drilling all titanium alloys including pure titanium, and CrazyMill Cool CF and CrazyMill Cool SF, which are tailored to filigree components and high-performance milling with outstanding surface qualities up to grinding quality.

Special milling tool package presented at EMO

In spring 2025, we take a big step forward and commission our new coating plant in Agno. With this important milestone, we have taken our production to a new level.

At EMO in Hanover, we present two new “crazy” tools - a drill and a milling cutter - and a special milling tool package for tibia and femur components. This new machining solution for knee implants is a breakthrough that is already attracting the attention of the market and setting new standards in terms of precision and reliability.

In November, the new website goes online, now integrated into the Mikron Group site. Key features: improved ToolFinder with newly integrated functions for cutting data and a redesigned area for tool returns, rework, regrinding, or complaints - all via a more intuitive and user-friendly interface.