Consulting & Engineering

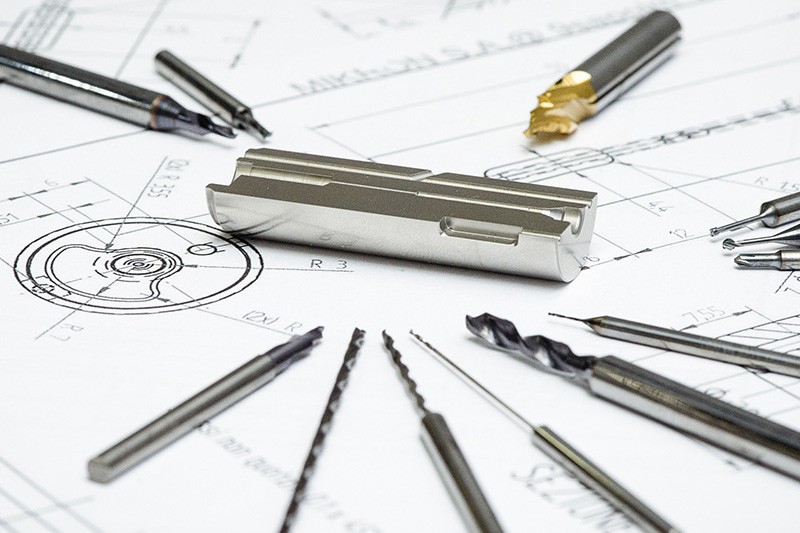

Consulting & Engineering: Your Partner for Optimal Machining Solutions

Mikron Tool offers comprehensive consulting and engineering services to optimize your manufacturing processes. From selecting the perfect tool to developing complete machining solutions, our experts are your partners in precision and performance.

Consulting & Engineering: From Idea to Optimal Result

With a high-performance tool from Mikron Tool, you're not just buying ground carbide; you're gaining a partner dedicated to achieving maximum results. Our cooperation often begins long before a tool is purchased, starting with your unique challenge. Whether you need to select the right tool or develop a complete manufacturing process for a new workpiece, our expertise in consulting and engineering is at your service.

Expert Consulting: Finding the Right Tool for the Job

A successful machining process starts with the right questions. Our specialists dive deep into your manufacturing reality to ensure you get the perfect tool for your application. We analyze every variable:

- Material: What specific material are you machining?

- Machine & Setup: What is your machine's max RPM, spindle run-out, and tool holder configuration?

- Cooling: Do you use through-coolant spindles, and what is the maximum pressure?

- Required Results: What are the required tolerances, surface quality, batch sizes, and target cycle times?

This deep understanding allows us to recommend the ideal standard tool or suggest flexible, customized variants—from slight geometry adaptations to alternative coatings—to perfectly match your needs.

Custom Engineering: Designing Your Perfect Machining Process

When the challenge is more complex, our engineering know-how comes into play. If you need to define an entire machining cycle for a new component, our team can design the ideal process. We determine whether a standard tool is sufficient or if a more profitable combination tool can be used. Our specialists are experienced across all machine types, from CNC milling centers to transfer machines and automatic lathes, ensuring we develop the most efficient and economical solution for your workpiece.

CrazyService Products: Test, Optimize, and Perfect Your Process

How can you be sure you've found the right solution before committing to serial production? For this, Mikron Tool developed CrazyService Products. Our dedicated Technology Center provides a team of tool specialists, machining engineers, and programmers to test, validate, and perfect your process without using your own machine capacity.

Our service packages range from simple tool tests before a purchase to full-scale project development, including:

- Tool Evaluation and Recommendation

- Defining Optimal Cutting Parameters with CAM Programming

- Tool Life Tests to Calculate Cost-Per-Part

- Complete, Documented Solutions for Producing a New Part

We deliver not just tools, but actionable know-how, test reports, measurement protocols, and data to guarantee your success.

A Partner to Machine Manufacturers

We work closely with machine manufacturers from the very beginning of a new project. By integrating our engineering expertise and high-performance tools during the bidding stage, we help create the most competitive and capable machine solutions.

Contact us here to learn more about what’s possible with Mikron Tool.