Accurate and efficient milling with CrazyMill Cool Z2

Product summarize

The newly designed, through-shaft cooled roughing and finishing cutter sets new standards in the milling of grooves, pockets and walls in terms of cutting speeds, performance, tool life and surface quality. It combines HSC (high-speed cutting) and HPC (high-performance cutting), thus becoming an HSPC (high-speed performance cutting) milling tool.

The selected tungsten carbide, the geometry, the coating and especially the through-shaft coolant supply, which ensures perfect cooling of the cutting edges and removes the chips cleanly from the work area, support high cutting speeds, high depth feed ap (up to 1 x d) and high feed rates.

Three versions of cylindrical (small chamfer of 45°) and toric (corner radius) micro-milling tools are available in diameter of 0.3 – 6.35 mm (.0118" - .250", fractional inches available): a short one for maximum milling depths of up to 1.5 x d, a medium one up to 3 x d and a long one up to 5 x d. All three versions have a cutting head of 1.5 x d.

General milling information

Down-cut milling and up-cut milling

When milling pockets or walls, for example, Mikron Tool recommends up-cut milling. This because with down-cut milling the thickness of the chips at the beginning is zero and increases until the exit. chip. In this case, high cutting forces push the milling tool and the work piece away from each other.

Entry into the material during milling

During milling with direct entry into the material, very thick chips are produced and the milling tool is subject to asymmetrical stress until it is working with its entire diameter in the material. These stresses can affect the tool life of cutting edges, especially in hard and tough materials such as heat-resistant steel or titanium. We, therefore, recommend two different more gentle types of entry apart from direct entry with full feeding:

1. Direct milling without reducing the feed in general steels (material group P), aluminum, etc. (material group N)

2. Reduced feed: Direct milling into the material with an approx. 50% less feed in hard and tough materials such as heat-resistant steels or titanium

3. Indirect entry (also called roll on entry): Indirect milling in the material (clockwise entry into the material in one radius) and 30% less feed in hard and tough materials such as heat-resistant steels or titanium

Conventional slot milling

For cutting values, see cutting data chart Conventional Slot Milling!

Advantages:

- Conventional 3-axis CNC machines can be used

- High metal removal rates if the conditions are stable (stable tool and work piece clamping)

- Simple programming

Disadvantages:

- Sensitive to vibrations (several milling steps might be needed)

- Limited precision in groove milling (for example, perpendicularity or surface), sometimes must be machined in several milling steps ap.

- Produces high radial forces

Trochoidal slot milling

For cutting values, see cutting data chart Side Milling / Trochoidal Slot Milling!

Additional parameter recommendation:

- Milling tool's diameter d1 in comparison to the groove: d1 = max. 70% of flute width

- Cutting depth ap = depending on material and milling tool type, see cutting data chart

- Cutting width ae = max. 10% of milling tool's diameter d1

- Cutting speed = depending on material and milling tool type, see cutting data chart

- Feed per tooth fz = depending on material and milling tool type, see cutting data chart

Advantages:

- Generates smaller radial forces and fewer vibrations

- Higher precision due to smaller tool deflection (because of small radial forces)

- Better chip evacuation

- Less heat being generated

- Gentle to the tool, especially in stainless, acid-resistant and heat-resistant steel as well as titanium alloys and hence longer life

Disadvantages:

- A dynamic machining center as well as modern machine control is a must

- More programming costs

- Greater machining time

Penetration

Spiral interpolation offers the best and most gentle method of penetration.

The methods of penetrating using a linear ramp or, if a ramp is impossible, direct penetration can also be used with milling tools such as CrazyMill Cool (milling tool cuts over center).

Penetration with spiral interpolation

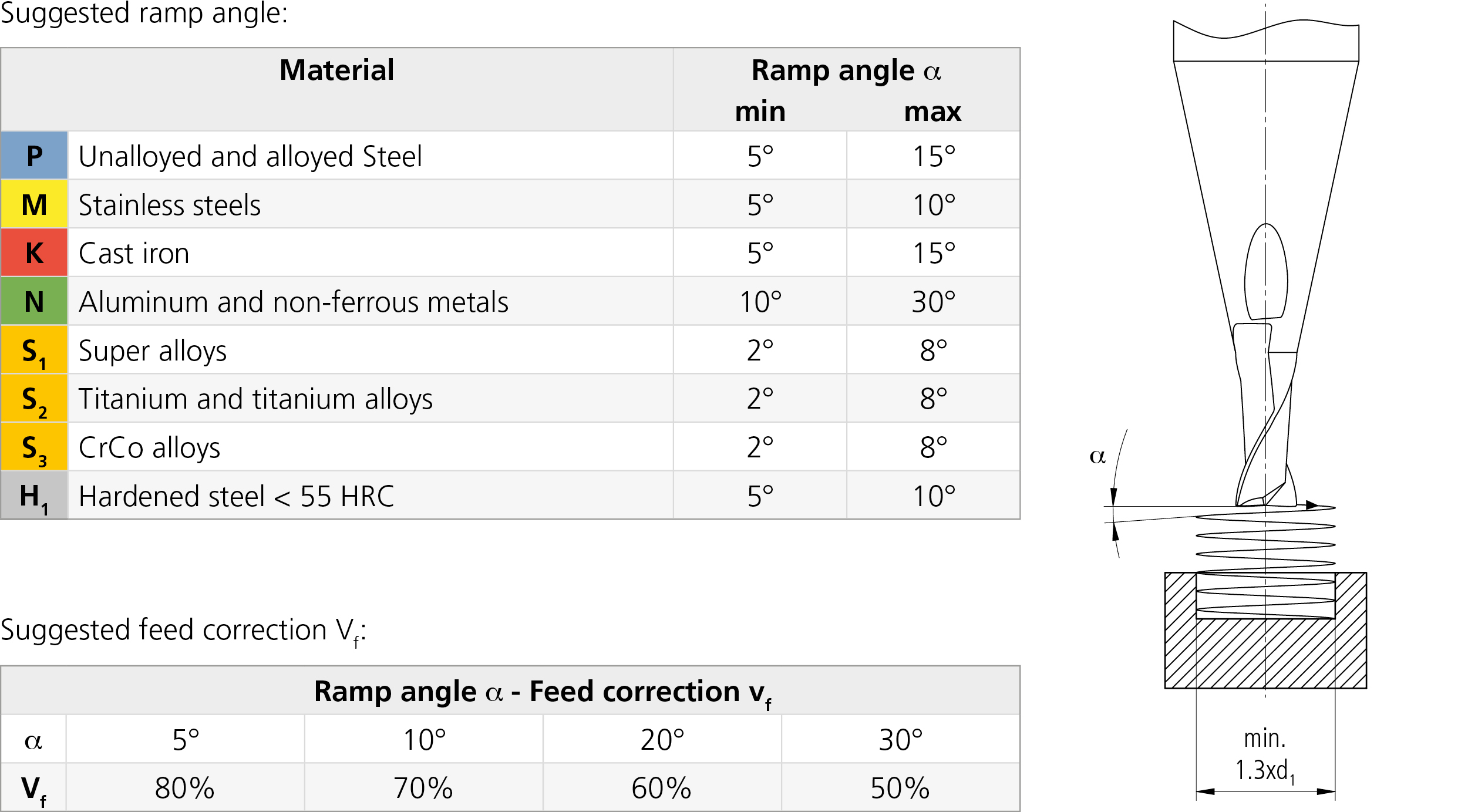

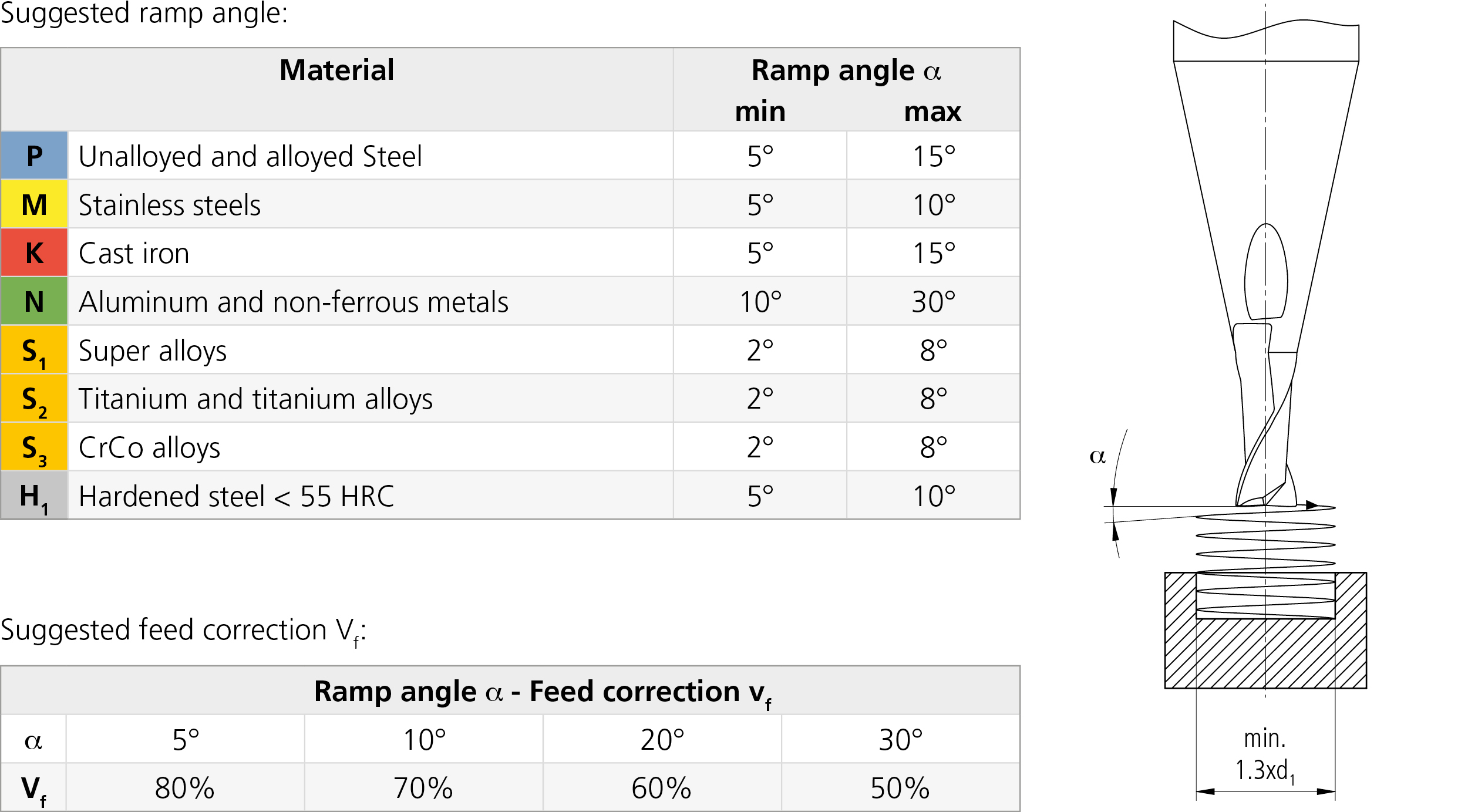

Please note that the minimum diameter to be produced must be 1.3 x tool diameter d1. The minimum and maximum penetration angle α as well as the feed correction Vf must be maintained depending on material.

Penetration using a linear ramp

A milling tool that can penetrate axially is needed for the penetration (milling tool must cut in the center, see symbol).

The minimum and maximum penetration angle α as well as the feed correction Vf must be maintained depending on material.

Direct penetration (without ramp)

A milling tool that can penetrate axially is needed for the penetration (milling tool must cut in the center, see symbol).

A maximum feed of 30% of the given value is used in vertical immersion.

Tested and approved

Mikron Tool has determined the ideal cutting parameters (ratio of tool life to process reliability) for the use of CrazyMill Cool Z2. These are listed in the cutting data charts for the milling tool's diameter, milling tool type and type of machining (slot milling, side milling) as well as the material to be machined. Unique cutting data tested at Mikron Tool such as cutting speed vc, feed per tooth fz and cutting depth ap or cutting width ae ensure quick and safe machining.

The cutting data chart overview for material group, type of material, degree of hardness or tensile strength, material number, DIN and AISI/ASTM/UNS ensure a quick determination of the cutting data to be used.

Packaging

An impact-resistant and user-friendly drill packaging is absolutely necessary for CrazyMill Cool Z2. Mikron Tool offers all tools of the CrazyMill Cool family in a high quality, single package.

Notes or further questions

Please find more information about tool holders, cooling or lubrication under “Additional Info”.

Mikron Tool has an international team of cutting technology experts who are pleased to answer your questions (how to use a drill, tools, machines, tool holders, cooling, machining process…).

Use this link to contact us directly.