The turnkey solution for Torx® sockets

-

Mikron Tool presents a new concept for hexalobular medical screws made from titanium or stainless steel.

900 million medical screws are produced every year with a strong upward trend. Efficiency in production plays therefore an increasingly important role: every saved second is an advantage in terms of money and time. The challenge is to increase productivity while ensuring highest quality.

A combined drill, a micro endmill, a good machining strategy and perfectly tuned parameters, that's all Mikron Tool needs to increase efficiency when machining medical screws with hexalobular socket made from titanium or stainless steel. Our revolutionary turnkey solution enables 50% faster machining time while guaranteeing maximum profile accuracy, excellent surface quality and minimum burr formation. This means: time and money savings combined with precision and quality.

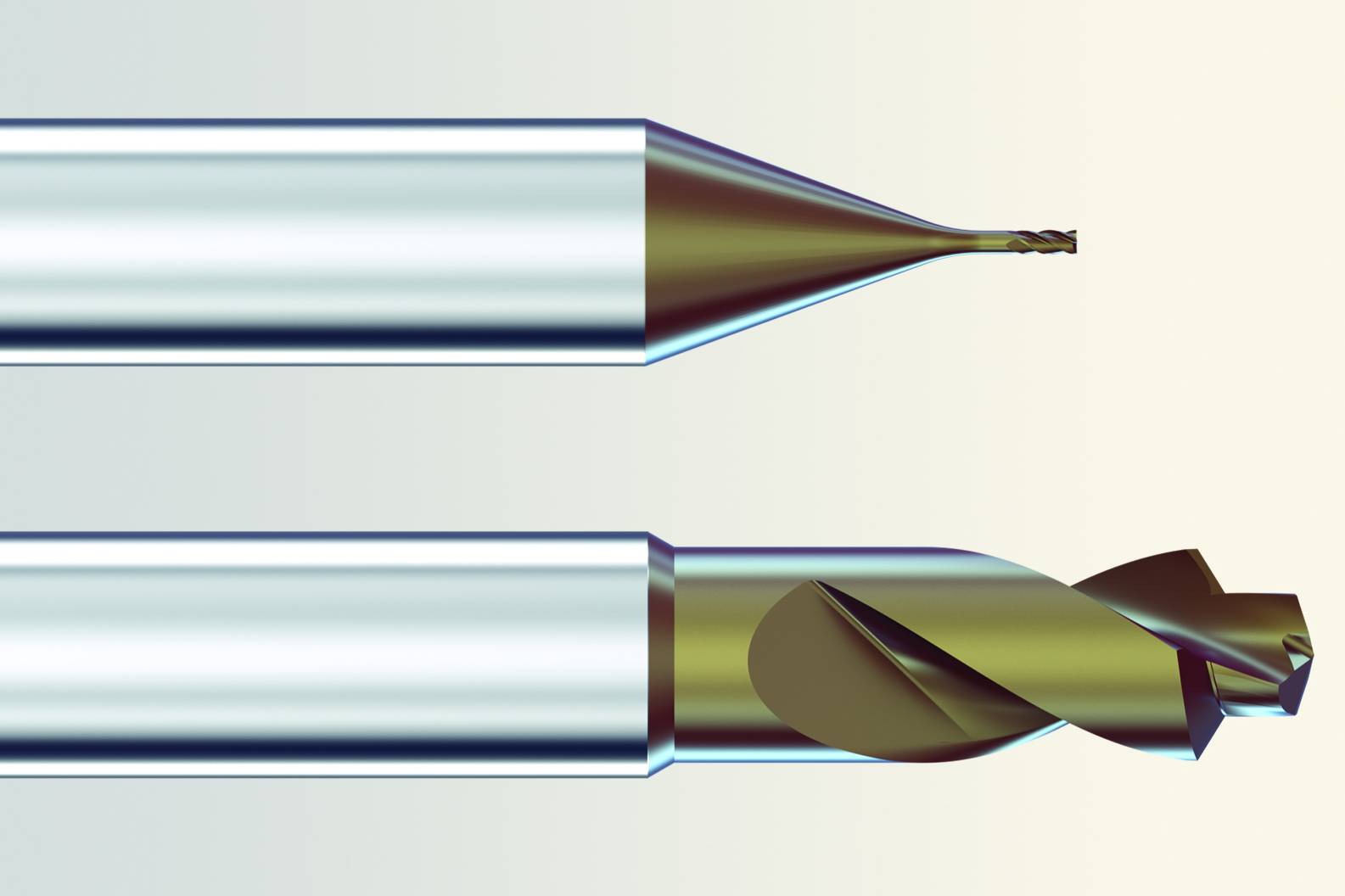

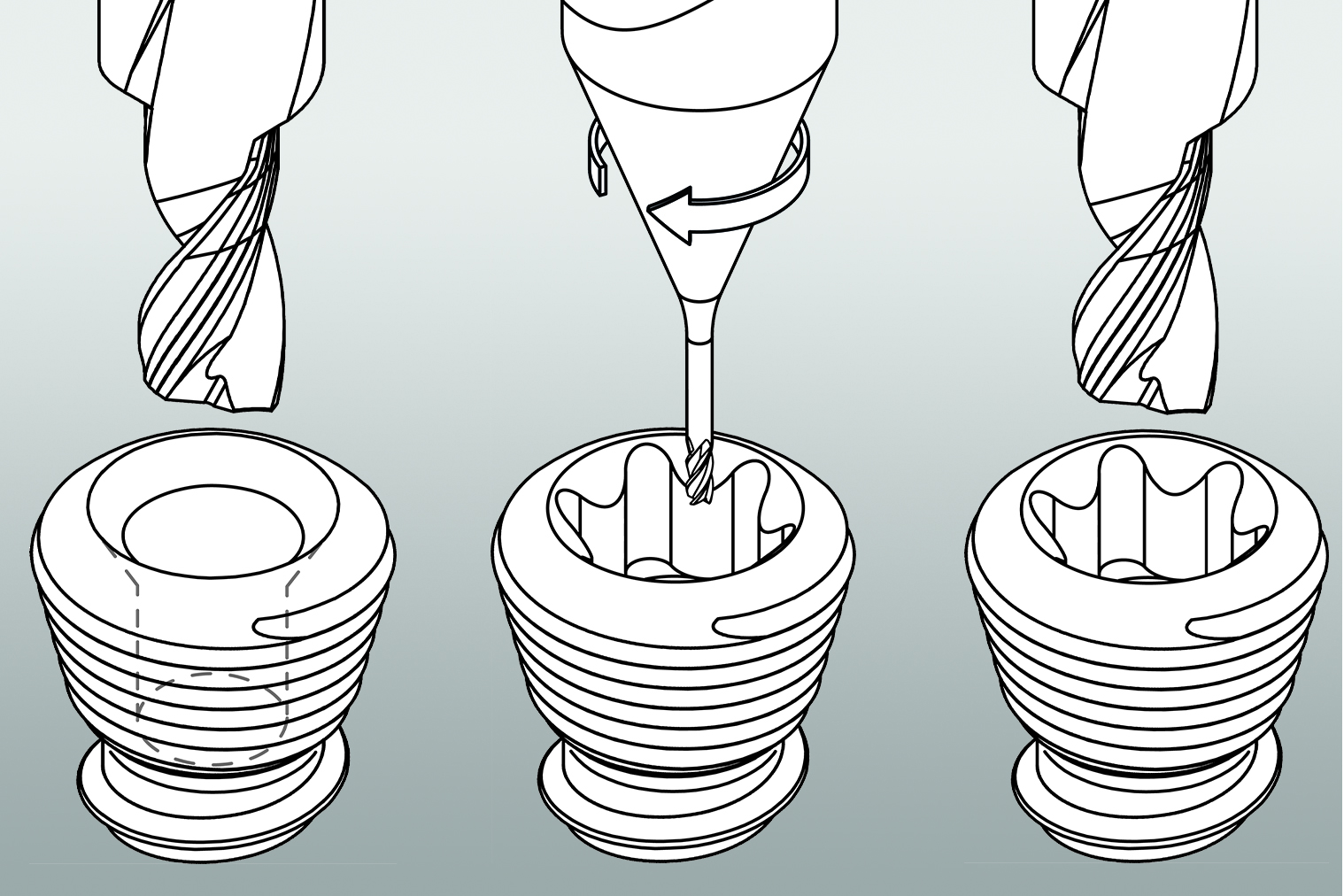

2 tools perform in 3 steps 4 operations: drilling, chamfering, milling and deburring. The combined drill CrazyDrill Hexalobe applies both a center bore and a 120° chamfer in a first step, already achieving high surface quality. That's not all: the same tool is reused in the last operation and ensures a nearly burr free surface. In a second step, our micro endmill CrazyMill Hexalobe made of special carbide comes into play and mills the hex lobular socket either by helical interpolation (only for titanium) or side milling (for stainless steel and titanium). Its high rigidity enables machining with high feeds and massive stepover, while ensuring a very high-profile accuracy. In fact, the tolerance range is very tight and must be rigidly respected in order to guarantee profile precision and side perpendicularity of the hex lobular socket from the first to the last screw.

This strategy enables a faster machining process and thus higher productivity. At the same time long tool life and highest quality is guaranteed.

The micro endmill CrazyMill Hexalobe is available for Torx® T4 – T30, in diameters from 0.2 to 1 mm (.0078” to .039”), for milling depths of 3.5 x d and 5 x d and, depending on the diameter, with 3 or 4 flutes. The Crazy Drill Hexalobe combination drill is available for Torx® T4 – T30 and in diameters from 0.9 to 3.8 mm (.035” to .150”). Ideally, these tools are used together as a package to achieve high performance and maximum quality. Two types of geometries have been developed for optimal machining of titanium and stainless steel. Both tools (for titanium and stainless steel) have a chrome-free, heat and wear resistant coating.

A package that includes not only tools but delivers also the best machining application strategy and the right parameters. Let the product or the performance video surprise you.