We love challenges

Tools are our passion, small dimensions are our specialty and hard-to-machine materials are our challenge. The everyday life of Mikron Tool is around these attributes.

Credo

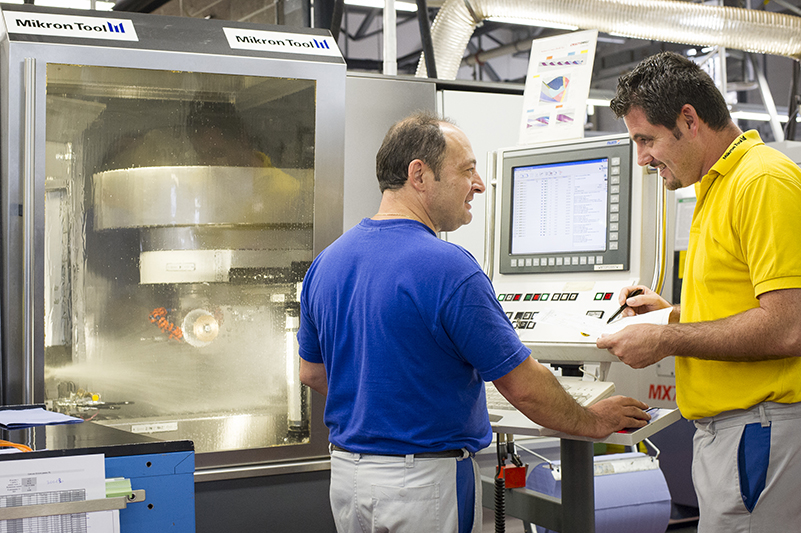

We are working daily to achieve a leadership position worldwide in high precision machining of small dimensions and challenging materials. This includes both the regular introduction of new and unique metal work tools on the market and the development of concrete solutions directly with the customers. In everything we undertake, the high level of competence is important. We are keeping up with that, whereby we concentrate on our strong points. Strong points such as best trained and motivated employees, intensive development activities or investing in most advanced production technologies.

Innovation

"Mikron Tool shows healthy growth due to its innovative products"

A product is considered NEW at Mikron Tool only when it is unique and with high added value for the user. Without doubt, this is true for every single CrazyLine product. The proof: Twice already new developments of Mikron Tool were distinguished with the Prodex Award, a Swiss innovation prize for the best new developments in the field of manufacturing and production.

Our goals are clear: To surprise every year with original "crazy" novelties, to expand regularly the product lines, to optimize the existing boring tool examples and develop new ones. To achieve all that, it is necessary to actively pursue innovation in all areas of the company. Therefore, we use the latest technological knowledge, constantly optimize our processes, train ourselves regularly and exchange our knowledge among us. In addition, we rely on the collective intelligence of a motivated workforce. Our employees bring not only their proposals for improvement but also accept responsibility for the realization of their ideas.

The offer

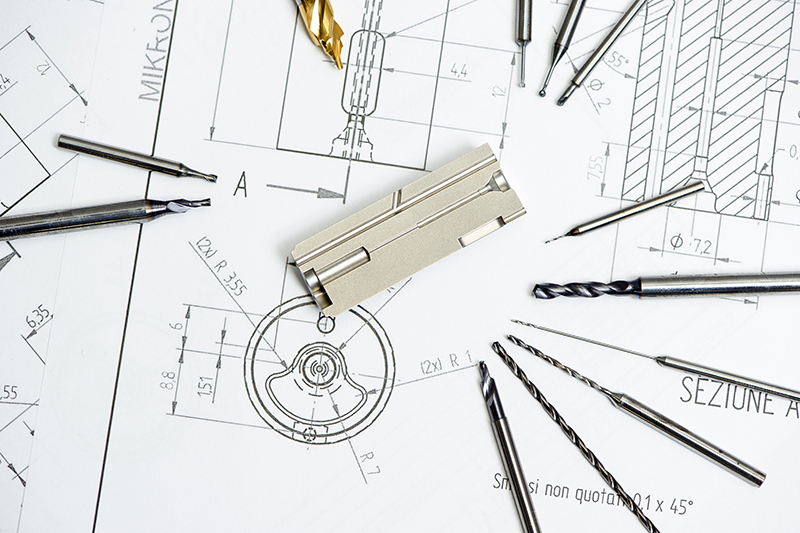

Our offer is always about the adequate processing solution with tungsten carbide cutting tools: the customer selects either a solution that is specific to him or a product from the standardized tool program, which is available directly from stock. The main emphasis is on small dimensions in the cutting tool sizes with diameter from 0.1 to 8 mm (.004" to .315").

In the area of customer-specific tools, the offer comprises the centering and chamfering, milling, turning, grinding or deburring and up to complex combination tools in the diameter range between 0.1 mm and 32 mm (.004" - 1.260"). These tools, with a focus on the machining of difficult materials, offer a high degree of precision and applications. A single customer-specific tool can often replace a number of standard tools, reduce significantly the processing times while increase precision. Hereby not the costs per tool but the costs per manufactured part are in the foreground.

The catalog tools of Mikron Tool come with highest performance, best quality, and precision directly from our stock. The offer comprises not only various types of drill bits, but also tools for centering, milling and deburring in the diameter range from 0.1 to 8 mm (.004" to .315"). However, flexibility and adaptation to the requirements of the client is of major importance here. Drill bit size, best suitable geometries, the right coatings - the possible variants are practically endless.

The segments

Our customers come from a wide variety of industry segments, wherever high volume production or where precision repeatability is crucial. Also, where small dimensions require extreme tolerance and when difficult to machine materials are an issue.

Automotive industry, watchmaking and jewelry industry, aerospace technology, medical and dental technology, machine and apparatus construction, tool and mold making, transport and conveyor technology, electric and electronics, writing instruments, food industry, petrochemical industry, fittings, hydraulic and pneumatic devices, household appliances are segments where our tools are successfully being used.