Finishing in grinding surface quality

-

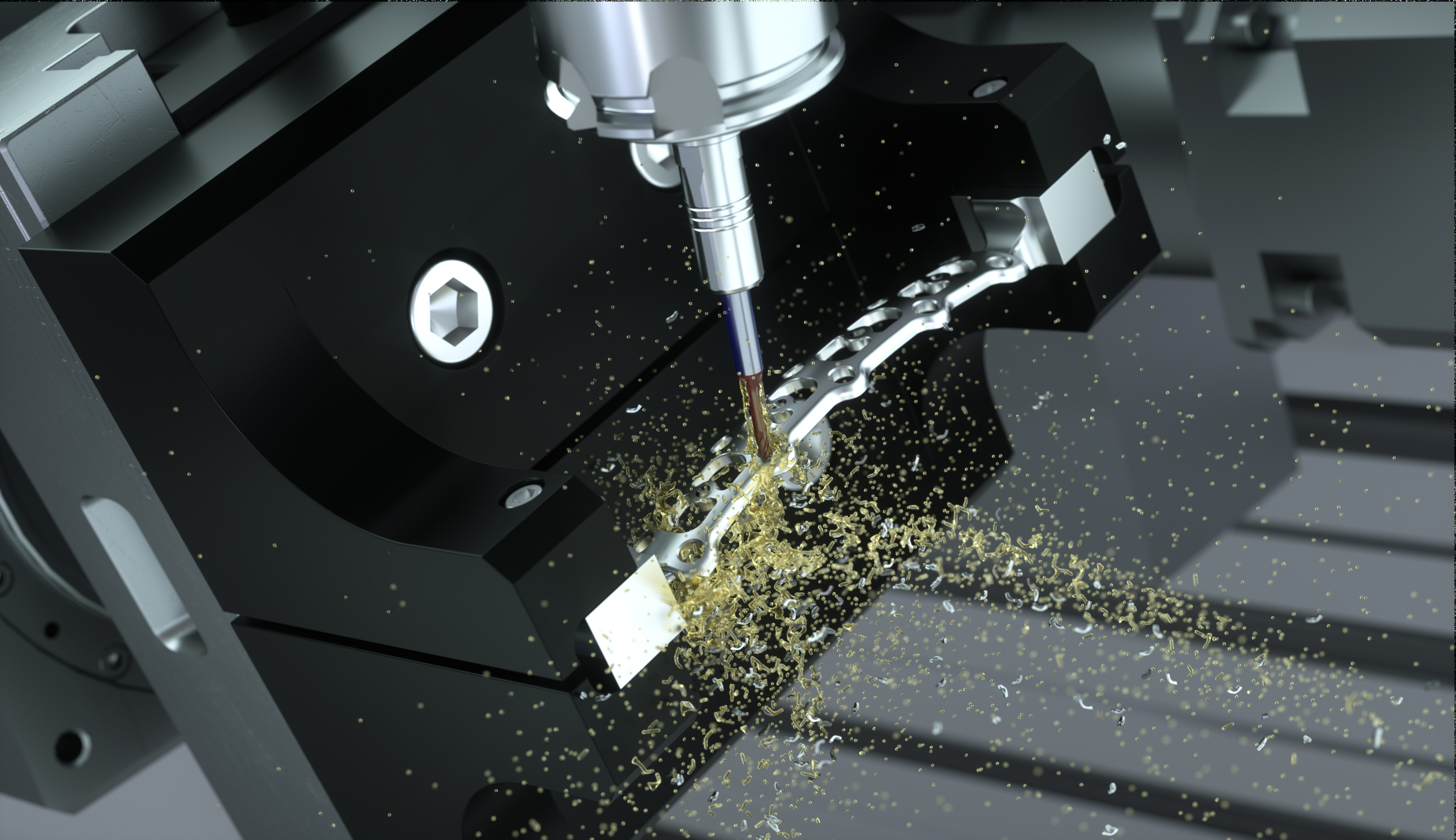

New milling cutter with integrated cooling now available from stock

CrazyMill Cool products have been developed for milling in small dimensions with highest performance and quality. Now a new “family member” has been added: a four teeth Finishing Milling Cutter with shank integrated cooling, available from stock in the diameter range of 1 to 8 mm and for milling depths of up to 5 x d. This milling cutter is suitable for machining all materials up to a hardness of 54 HRC. Nevertheless, this new tool has been developed focusing on stainless steels, titanium, heat resistant alloys based on nickel and chrome-cobalt-alloys. Hence it is not surprising that these tools are especially convincing with highest performances when working with these materials.

All characteristics of the new milling tool are designed to reach highest milling performance as well as best surface quality. Primarily, this means that due to poor heat conductivity of stainless and heat resistant materials, overheating of the tool cutting edges must be avoided. Several factors are instrumental.

Cooling, cooling, cooling

Especially machining stainless and heat resistant steels dictate that heat needs to be controlled, because it cannot be absorbed by the material and chips. Our milling cutter handles this with 3 up to 5 coolant ducts integrated in the tool shank. This delivers constantly a massive coolant jet directly to the milling area, independent of the work position and possible interfering edges. The tool receives continuously coolant and does not risk any overheating. Hence it is possible to simultaneously work with high speeds, feeds and working depths. This results in a high chip volume and excellent tool life. Another advantage is the continuous flushing of chips from the milling area. This avoids a repetitive cutting up of chips and the subsequent damaging of the milled surface and in turn facilitates in conjunction with the

corresponding geometry a maximal surface quality.

The geometry: fine-tuned in detail

The geometry is entirely focused on reaching a high milling performance and surface quality. There is a flute-angle of 30º on the shorter tools (with cutting length 2 x d), whereas the longer versions (with cutting lengths 3.5 x d and 4.5 x d) have a progressive flute-angle increase from 30º into 40º. For both versions, the transition of 30º from the radius to the cylindrical section creates an optimal cutting-edge corner stability and smooth milling without vibrations.

Speeding is allowed

With its four teeth, the new milling cutter is well suited for Pre-finishing and Fine-finishing. For maximal milling performance, the manufacturer clearly defined the corresponding milling cycles and provides detailed cutting parameters. Mr. Alberto Gotti (manager of R&D) points out that the tool users often do not venture to work with high cutting parameters in the beginning and thus miss to take full advantage of the performance capacity of these tools. No need to reduce the parameters because these are all based on practical tests with corresponding materials and specific tools. Therefore, one should adhere to the indicated speeds. Slower is not safer in this case.

With the Version N (Milling depth = 4,5 x d) it is for instance possible to mill at the radius and simultaneously at the cylindrical section and therefore use the entire length of the tool. Especially when finishing or also multipass millingwith the head section, Mikron Tool recommends to work with an inclination of 15º. With this, all four cutting edges are engaged in the milling operation which results in a better surface quality. First very positive experiences have been made with medical devices when milling bone plates made of titanium.

Increased challenge results in impressive performance

With all materials an efficiency increase is possible thanks to cooling and geometry. This stands out especially when using CrazyMill Cool to machine Titanium or Stainless and heat resistant materials. There are several strategies for conventional tools: Some manufacturers recommend to mill with fast feed and speed but with smaller milling path (ap), others try increased milling depths but reduce speeds and feeds. This is where the new “crazy” cutter differentiates in its use. High machining data are recommended for all parameters. An example? Pre-finishing a titanium work-piece with a milling cutter Ø 3 mm with 150 m/min speed, feed of 0.025 mm/U and a milling path ap of 2 x d reaching with this a chip removal rate of 2864 mm³/min and simultaneously high tool life of more than 60 m.

Especially for high standards

Two versions of the CrazyMill Cool Ball Z4 are available with especially long cutting edges. These have progressive spiral flutes (from 30º to 40º) which guarantee a vibration less milling and thus afford an additional improvement of the surface quality. The angle of 30º at the tip prevents a too accentuated interface between the cutting edges and the cylindrical section and therefore reduces the risk of cutting edge break-out. These versions are especially suitable for side milling because in one or few mill paths the entire depth can be machined. Independent of the milling width the Ra-values of the X-Axis (perpendicular to the milling direction) between 0.1 and 0.3, in the Y-Axis (along the milling direction) are in the range of 0.06 and 0.1. These are values which are usually in the range of what’s achieved with Fine-Grinding or even Ultra Fine-grinding.