A milling cutter

for slots and pockets

in smallest spaces

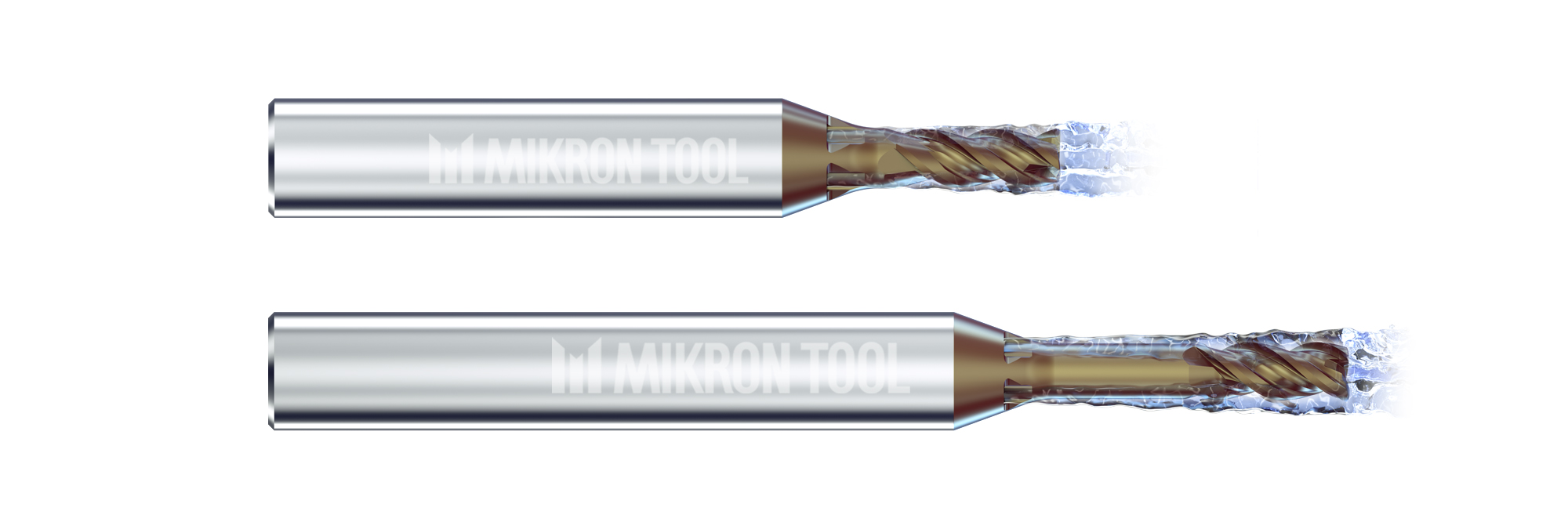

CrazyMill Cool P&S square and corner radius is an innovative, 3-flute mill with in the shank integrated coolant supply ducts which Mikron Tool developed specially for rough and finish milling of stainless steels, titanium, super alloys and CrCo alloys. It is also very well adapted for other materials such as steels up to max. 40 HRC, cast iron, non-ferrous metals and plastics. Based on its ability to plunge directly with up to 1 x d vertically into material, it becomes a “plunge-mill” i.e. “drill-mill” or “milling drill” for metal and is especially suitable to mill grooves, pockets and faces in smallest spaces in general and, with Type A, specifically for keyways (feather keys) as found in drive shafts for example.

Both square and corner radius solid carbide shaft endmill is available in diameters from

1 – 8 mm (.039” - .315”, fractional inches available) and for depths up to 5 x d.

CrazyMill Cool P&S – revolutionary to the detail

This square respectively corner radius tungsten carbide shaft endmill with integrated cooling available in standard endmill sizes from 1 to 8 mm (.039” to .315”, fractional inches available) is new and unique in its design. This innovative tool can “drill” vertically into material up to 1 x d and then move sideways to mill slots and pockets into solid material. Hence operations like feather key-milling (with Type A) can be executed rapidly and process safe in smallest spaces.

The following features distinguish this small milling bit CrazyMill Cool P&S which shows outstanding performance especially in nickel-based alloys:

- Geometry of the head section

- Edges and flutes geometries

- Through cooling

- Ultrafine grain carbide

- High-performance coating

Geometry of the head section

A specially designed and extra wide chip space in the head section allows to receive chips during the drilling process and evacuate them sideways through the flutes. A correction in the center stabilizes the middle cutting edge and prevents chipping, reduces the entry force and guarantees a significantly higher tool life.

Cutting edge and flute geometry

A special cutting geometry facilitates process stable and vibration free “drilling” (vertical plunging) and guarantees thus a very good stability. Customized flute and relieve angles together with stable cutting-edge angles prevent the lateral hooking up and chipping of the edges often caused by vibrations. The enlarged flutes create sufficient chip space to allow perfect chip evacuation.

Integrated cooling – patented

The three to five (depending on shank diameter) coolant ducts in the shank provide a constant and massive coolant stream which prevents the over-heating of the cutting edges and facilitates flushing of chips from the milling area. This cooling concept is especially well adapted for pockets and slots since chips can be flushed even from tight nooks and crannies. Besides, it also prevents the repetitive dismembering of chips in the milling area avoiding damage to the edges and at the same time has also a positive influence on the surface quality, which when milling even into solid material reaches finishing quality. The cooling generally guarantees longer tool life and facilitates at the same time higher chip removal rates when compared to conventional types of carbide milling cutters with external coolant supply.

Ultrafine-grain carbide

A specially developed ultrafine-grain carbide with high tenacity fulfills all requirements in regards to mechanical characteristics. The robust carbide shank supports a stable and vibration free milling process. Hence best precision and surface quality are obtained.

High-performance coating

The high-performance coating SNP is heat and wear resistant, prevents a sticking and buildup of the edges while also guaranteeing an optimal chip evacuation. This results in long tool life of the milling cutter.

CrazyMill Cool P&S Video

CrazyMill Cool P&S Video

Accurate and efficient milling

Accurate and efficient milling

CrazyMill Cool P&S Video

CrazyMill Cool P&S Video

Accurate and efficient milling

Accurate and efficient milling