CrazyDrill Crosspilot

for holes on inclined, convex

and concave surfaces

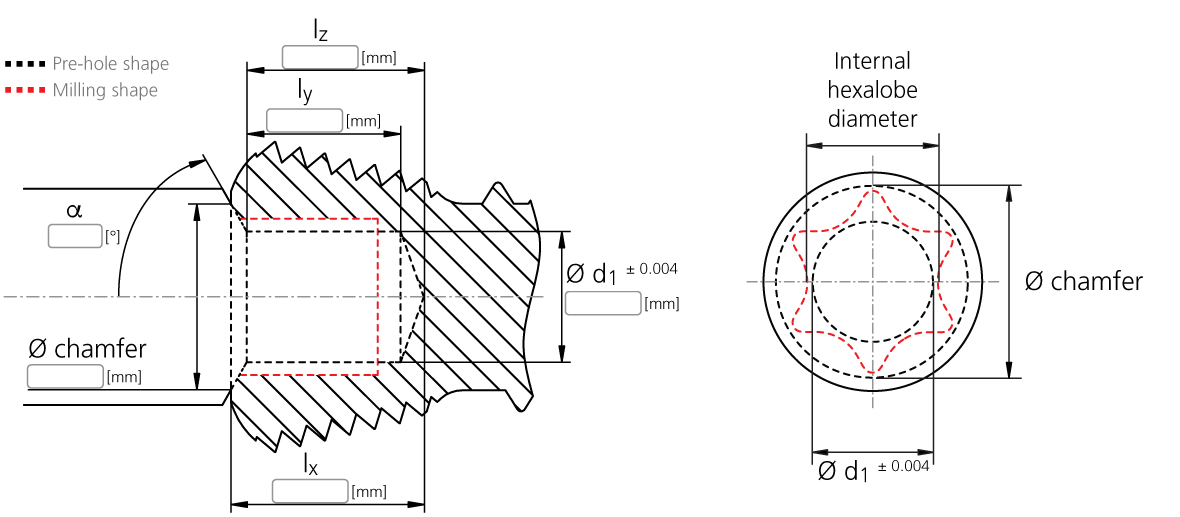

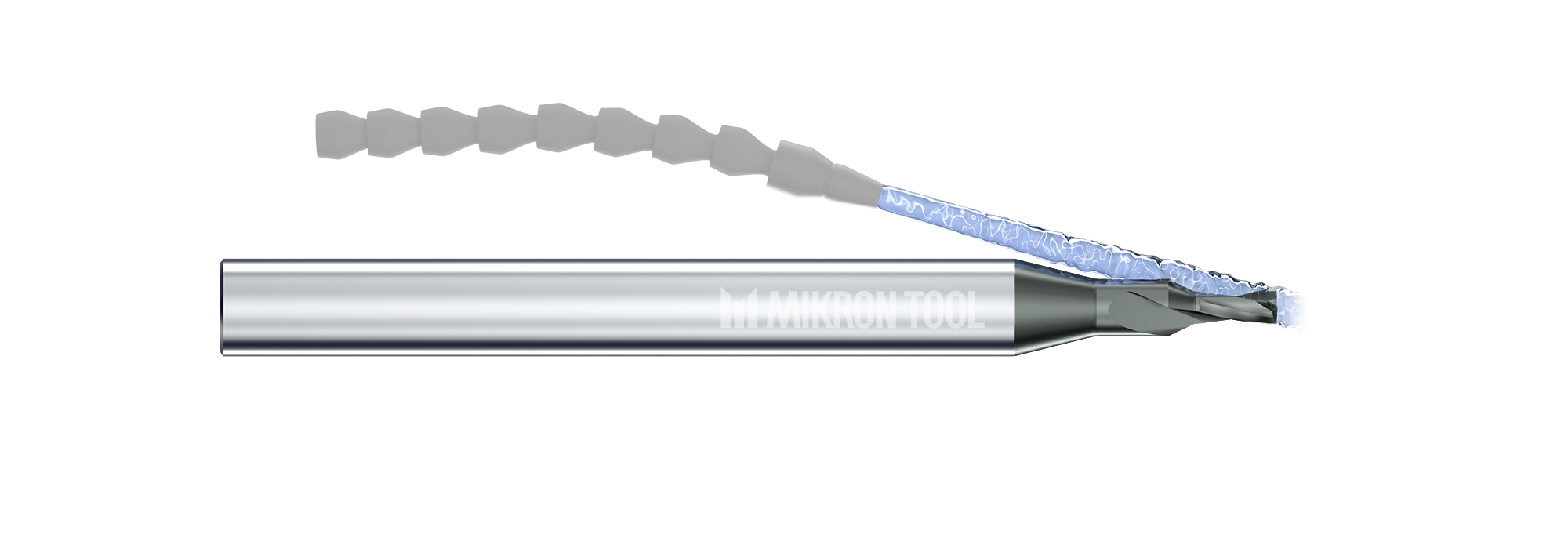

The coated tungsten carbide drill for steel, stainless steel materials, titanium and nonferrous metals (CrazyDrill Crosspilot from Mikron Tool) is a unique specialist for holes on inclined, convex and concave surfaces. It produces pilot holes directly in surfaces with up to a maximum inclined angle of 60°, which does not correspond to a DIN centering hole since no circular chamfer can be made on an inclined surface.

This means the solid carbide drill bit reduces the three steps needed up to now ( milling – centering – drilling) to two steps and simultaneously guarantees a higher degree of precision due to good guidance. Its compact and sturdy design provides for good position accuracy. Its geometry is designed for extreme applications. The 170° tip angle of the CrazyDrill Crosspilot affords the follow-up drill stability, thus preventing cutting edge breakage. The pilot drill can be supplied from stock in diameters of 0.4 mm to 6.35 mm (.016” to .250”, fractional inches available), suitable for the existing CrazyDrill program.

Drilling precision on inclined surfaces with CrazyDrill Crosspilot

Provided a tool meets a work-piece at right angles, centering or direct finish-drilling poses no problem. However, if the holes go diagonally through the part or if the surfaces are inclined, drilling becomes difficult. The forces exerted complicate the accurate drilling process considerably.

The design of the pilot drill CrazyDrill Crosspilot allows to drill a hole at an angle with up to a maximum inclination of around 60° to the surface. Due to its extreme drilling on inclined surfaces, it replaces the otherwise necessary milling operation and could therefore be called a milling drill bit for metal as well. The three steps of milling – centering – drilling" are reduced to two with CrazyDrill Crosspilot: pilot drilling - drilling or deep-hole drilling. This guarantees a higher degree of precision due to good guidance.

A feature of the CrazyDrill Crosspilot is the compact and sturdy design which translates to position accuracy. The drill with a tip angle of 170° provides correct guidance to the follow-up drilling and prevents cutting edge breakage. When using the long CrazyDrill drill suitable for the CrazyDrill Crosspilot, no step can be detected at the transition and this often makes additional finishing of the surface unnecessary.

Due to these features CrazyDrill Crosspilot is a true industrial drill which can be used in any industrial sector.

Important: adapted to the CrazyDrill program

CrazyDrill Crosspilot is perfectly adapted to other types of drill bits in the CrazyDrill line. With a diameter range of 0.4 to 6.35 mm (.016” to .250”, fractional inches available) this pilot drill is perfectly suitable as preparation for the deep holes produced by CrazyDrill. Diameters are available from stock up to 4 mm (.157”) in increments of 0.05 mm (.002”), and in increments of 0.1 mm (.004”) thereafter. The tolerances (m5) are so defined that there is no measurable step on the transition point from the pilot hole to the deep hole when using CrazyDrill drills.

What does this special tool bring to the user? It can help to produce deep holes on inclined surfaces in the most varied materials easily, accurately and safely, reduces machining operations by one step and hence saves time and money.

Your personal CrazyDrill Crosspilot

Mikron Tool also offers CrazyDrill Crosspilot in client-specific variants:

- Drill bits for hardened steel: Standardized up to 50 HRC, upon request up to 55 HRC

- Counterclockwise drill

- Drill bit sizes with diameters and lengths varying from the standard program

Do you need more information about our possibilities? Contact us here.

CrazyDrill Crosspilot Video

CrazyDrill Crosspilot Video

Accurate and rapid short drilling up to 2 x d

on inclined, convex or concave surfaces

Accurate and rapid short drilling up to 2 x d

on inclined, convex or concave surfaces