Clamping devices and cooling for pilot / short drills

General information

In the industry for metal work tools, shorter processing times are always in demand. At the same time, the requirements to the manufacturing precision and process reliability are growing. To fulfill these requirements, the "machine tool (all types of drilling machines) – spindle – tool – tool holder" system must be perfectly adjusted.

The following requirements have to be taken into account:

- For the machine tool: High level of stiffness, vibration isolation of the foundations, lightweight design of the moving parts, high concentricity accuracy of the spindle, pull-in forces of the machine spindle, intelligent and quick machine controls

- For the tool holder: High concentricity and balanced, friction-locked tightening of the tool

- For the tool: High concentricity, excellent balance quality (geometry and shank design), long tool life (tool material, geometry, coating)

Tool Holders

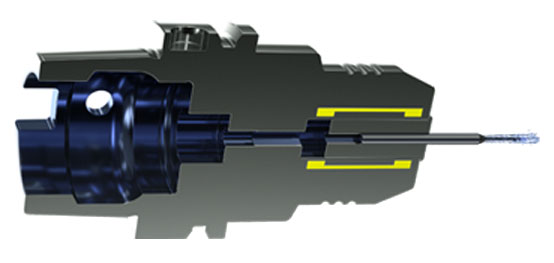

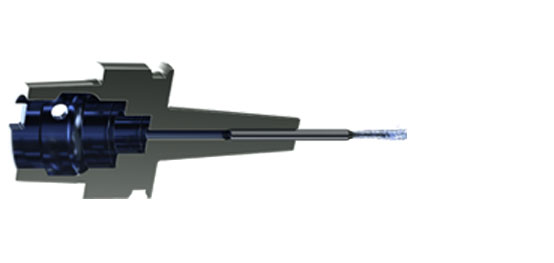

Hydraulic expansion tool holder

These ensure the high concentricity during drilling.

Characteristics:

- Concentricity: 0.003 mm (.00012”) (measuring point at 2.5 x D)

- Max. speed: 50'000 rpm / balance rate (G 2.5 / 25000 1/min)

- Precise concentric clamping

- High torque transmission

- Maintenance-free (closed system)

- No wear in the clamping diameter

- Longer (up to 4 times) tool life

- Adjustable clamping force

- Short tool change time (without additional devices such as, shrink fit device)

Application:

- High-precision clamping of tools with cylindrical shaft

- Universal tool holder for drilling and milling (roughing and finishing). Advantageous in the case of HSC processing (milling, for example on a small CNC milling machine) due to its shock-absorbing.

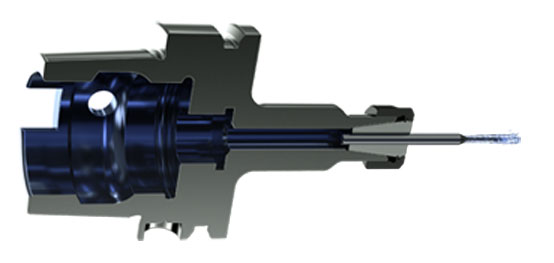

Shrink fit tool holder - shrink fit tool holder according to DIN 69871

These guarantee highest concentricity with secure friction-fit connection and form an optimal connection between the tool and the holder.

Characteristics:

- Concentricity: ≤ 0.003 mm (.00012”)

- Max. speed: 40'000 rpm

- Absolutely secure friction-fit force transmission

- Adequate for shaft diameter of 4 mm (.157”) (3 mm (.118”) are conditionally possible).

- Transmittable torque 2 to 4 times higher compared to the hydraulic-tool holder and the high precision collet tool holder.

- Average tool change time (shrink fit device is necessary)

- Suitable for machining in narrow spaces and interfacing edges due to the small overall construction size and longer versions

Application:

- Optimal for HSC machining, in particular also for smallest drill bits

- For milling and drilling tools with cylindrical shaft

Collet tool holder systems (ER collet chucks) according to DIN 6499-A / optimized precision collets

These guarantee highest concentricity.

Characteristics:

- Concentricity: 0.003 mm (.00012”) possible

- Max. speed: 40'000 rpm

- Average tool change time (a torque wrench is necessary)

Application:

- Clamping of tools with a cylindrical shaft in high precision collet according to DIN 6499

- Universal tool holder for milling (roughing and finishing) and drilling.

Balance quality

The balance quality of the collet tool holder is specially critical in high speed machining processes. The best possible balance quality guarantees not only reduced vibrations of the tool but increases tool life, improves surface quality and above all, protects the spindle bearings.

Types of drilling machines

CrazyDrill Crosspilot is used on all types of drilling machine, on CNC machining centers, automatic lathes or transfer machines.

- Minimum speed of 10’000 rpm (drill diameter 0.4 mm / .016”)

- Minimum concentricity of spindle 5 µm (.00019")

Cooling lubricant

For best results, Mikron Tool recommends the use of cutting oil as coolant fluid. Alternatively, emulsion of 8% or more with EP-Additives (Extreme-Pressure-Additives) can be used with good results as well.

CrazyDrill Crosspilot is cooled and lubricated through external coolant supply. In comparison to drill bit types with through-tool cooling such as CrazyDrill Cool (cooling comes out automatically at the ideal point of the drill tip), external cooling must be adjusted so that the cooling medium is conducted directly to the drill tip, thus cooling and lubricating the drill perfectly and flushing away the chips.