The two most important trade fairs of the metalworking industry will be held in parallel this year

-

And Mikron Tool is once more at both! AMB in Germany on September 13-17, 2022, and IMTS in the U.S. on September 12-17, 2022

After the forced break caused by the pandemic, the eagerly awaited AMB in Stuttgart is finally taking place again! And in Chicago, America's largest international exhibition for manufacturing technology, the IMTS (verlinken mit https://www.imts.com/), opens its halls at almost the same time. Mikron Tool will of course be present at both top-class events and has a lot to offer in terms of the latest developments with a focus on more and more efficient cutting technologies for difficult and most challenging materials in the micro range. That's all because the R&D department was working at full speed ahead. Here is a brief preview of the three new products that Mikron Tool will be presenting to the industry:

1) The new extraordinary milling cutter CrazyMill Cool Micro

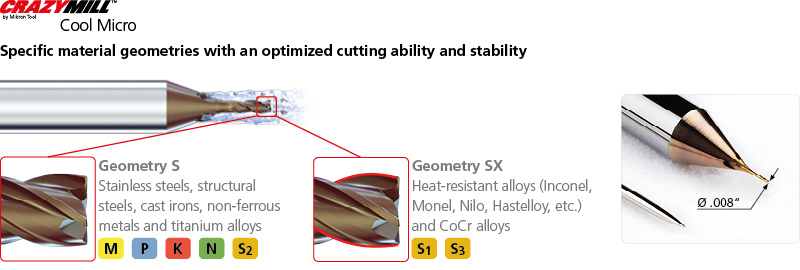

Mikron Tool engineers have succeeded for the first time in transferring complex high-performance geometries to micro-milling cutters and are launching the new CrazyMill Cool Micro series for roughing and finishing the most difficult-to-machine materials in the diameter range 0.2 mm - 1.0 mm (.008" - .039") with a maximum milling depth of 5 x d. It is the smallest of its kind with integrated cooling!

During development, special attention was paid to the different cutting behaviors of the various materials, which have a significant influence on the tool performance, especially in micro cutting. Therefore, this exceptional milling cutter is available in two variants, with different material-specific geometries (see figure below). As a result, it achieves incredible results: three times faster milling with up to twice the tool life (compared to commercially available milling cutters) and this with maximum process reliability. A "small" global sensation!

2) Mikron Tool's new engineering service offer

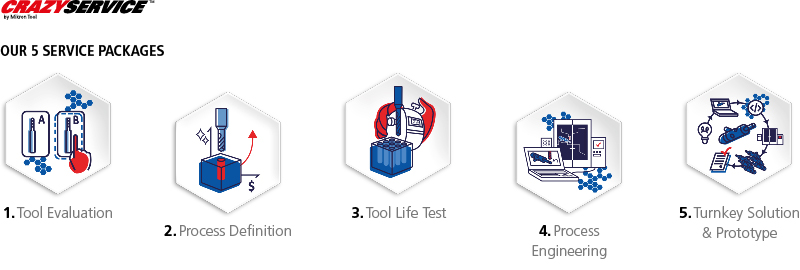

A significant step for the company and its partners is the worldwide launch of the new engineering services for machining challenging customer projects: the Crazy Service Products !

Thanks to many years of experience in high-performance machining of challenging materials in the micro range, Mikron Tool has acquired a high level of knowledge in terms of tool manufacturing, material science and machine tool technology. Mikron Tool now puts this knowledge at the service of its customers and offers, in addition to high-quality cutting tools, engineering solutions perfectly tailored to customer needs: from tool evaluation, optimization or redefinition of a process to the complete project including prototype or pilot series for product or process validation.

Customers can now benefit from the expertise of the machining specialists at Mikron Tool's Technology Center to optimize their processes without having to deploy their own resources.

3) An unprecedented drilling technology for the different types of titanium!

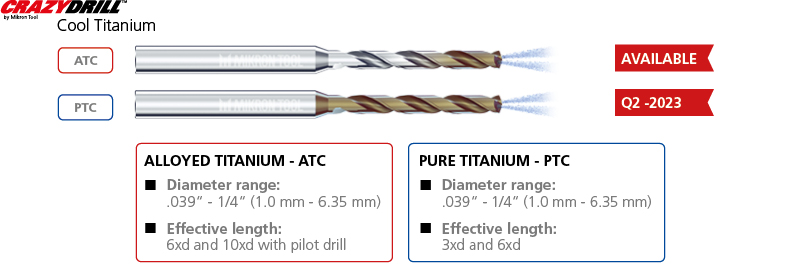

Here is another tour de force by Mikron Tool! Everyone knows that drilling titanium is highly demanding. Moreover, not all titanium is the same. Because pure titanium and alloyed titanium have completely different machining behavior. Mikron Tool responds to this with two new product developments in the diameter range from 1.0 mm - 6.35 mm (.039" - .250"):

CrazyDrill Cool Titanium ATC: Drill with 6 x d and 10 x d with pilot drill for alloyed titanium

CrazyDrill Cool Titanium PTC: Short drill 3 x d and drill 6 x d for pure titanium

These drills, which are perfectly tailored to the respective titanium grades, achieve maximum drilling performance with high process reliability at the same time. To produce precision components made of titanium, material-specific tools are of enormous advantage for cost efficient machining. At AMB and IMTS, Mikron Tool is presenting this unprecedented drilling technology for titanium to the industry for the first time, which means a significant increase in performance and quality for numerous industry segments such as aerospace, medical and dental applications, surgical orthopedics, and the jewelry and watchmaking industries.

Mikron Tool considers always standard market requirements

For the US market Mikron Tool provides tools with diameters in inches, from 1/64" up to 1/4" depending on the product line. Especially in the high-tech industries that are very relevant for the US market, such as aerospace, many dimensions are used in US standard units (inches).

The need for such dimensions is increasing and therefore Mikron Tool has introduced main dimensions in inches for a wide range of its drill and cutter families. The tool selection was based on the most used units in the industries concerned, with a special focus on tools for difficult-to-machine materials such as stainless steel, titanium, and superalloys. This topic will be spotlighted at IMTS 2022 alongside the new products, especially because of its importance for the US market.

Product and application presentation directly on site

Thanks to Mikron Tool's established partnerships with well-known tool machine manufacturers, visitors will be able to view various application presentations of the high-performance tools at their booths during the events. Information on the live demos is available directly at the Mikron Tool booth.

The machining specialists at Mikron Tool are excited to talk at the AMB and IMTS about the fascinating news and latest trends.

We very much look forward to seeing you in Stuttgart and Chicago!

AMB: Hall 3 Stand A82

IMTS: West Hall Booth #432279

We are crazy about AMB and IMTS!