Precise and efficient milling

with CrazyMill Cool Micro

Product summarize

The newly designed, through-shaft cooled milling cutter for roughing and finishing sets new standards in the milling of sides and slots and with helical interpolation in terms of cutting speeds, feed, performance, tool life and surface quality. It combines HSC (HighSpeedCutting) and HPC (HighPerformanceCutting), thus becoming an HSPC (HighSpeedPerformanceCutting) milling tool.

The selected tungsten carbide, the geometry, the coating and especially the through-shaft coolant supply, which ensures perfect cooling of the cutting edges and removes the chips cleanly from the machining area, support high cutting speeds, high depth feed ap and high feed rates.

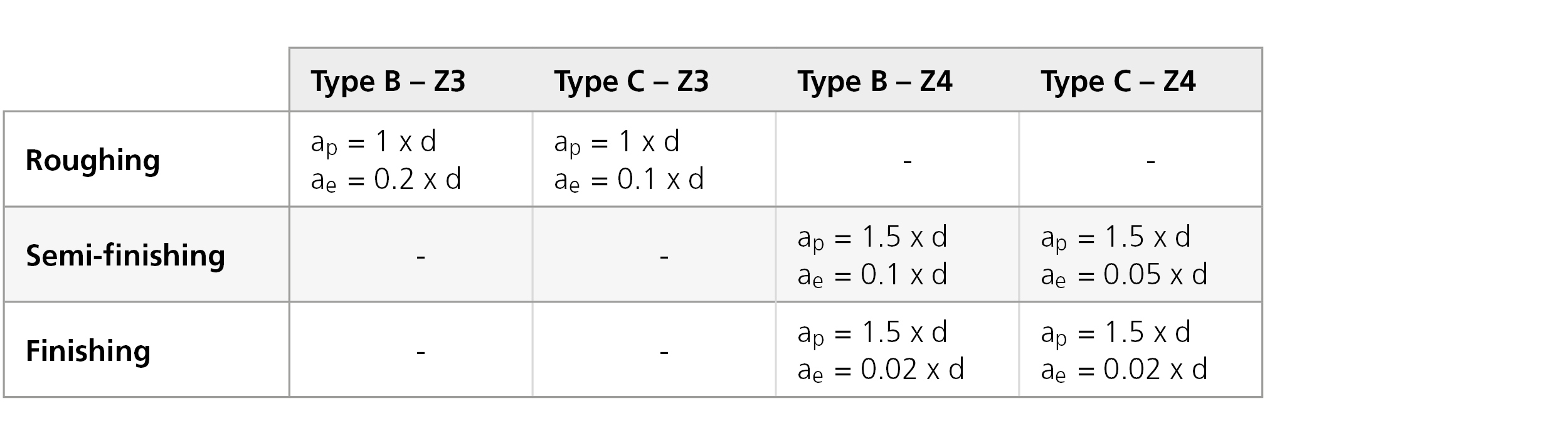

Two versions of square micro-endmills with two cutting-edge geometries each are available, in the diameter range from 0.2 up to 1.0 mm (.008“ up to .039“). Type B for maximum milling depth up to 3 x d (cutting length 1.5 x d) and Type C up to 5 x d (cutting length 1.5 x d).

General milling information

Climb milling and conventional milling

For side milling, Mikron Tool recommends climb milling. The chip thickness is greater at the beginning and decreases continuously, and the cutting forces remain low. With conventional milling, however, high cutting forces would push the milling tool away from the workpiece. Thus, the surface quality and precision of the workpiece decrease.

Side milling

Recommended cutting parameters

vc and fz = as indicated in the cutting data table

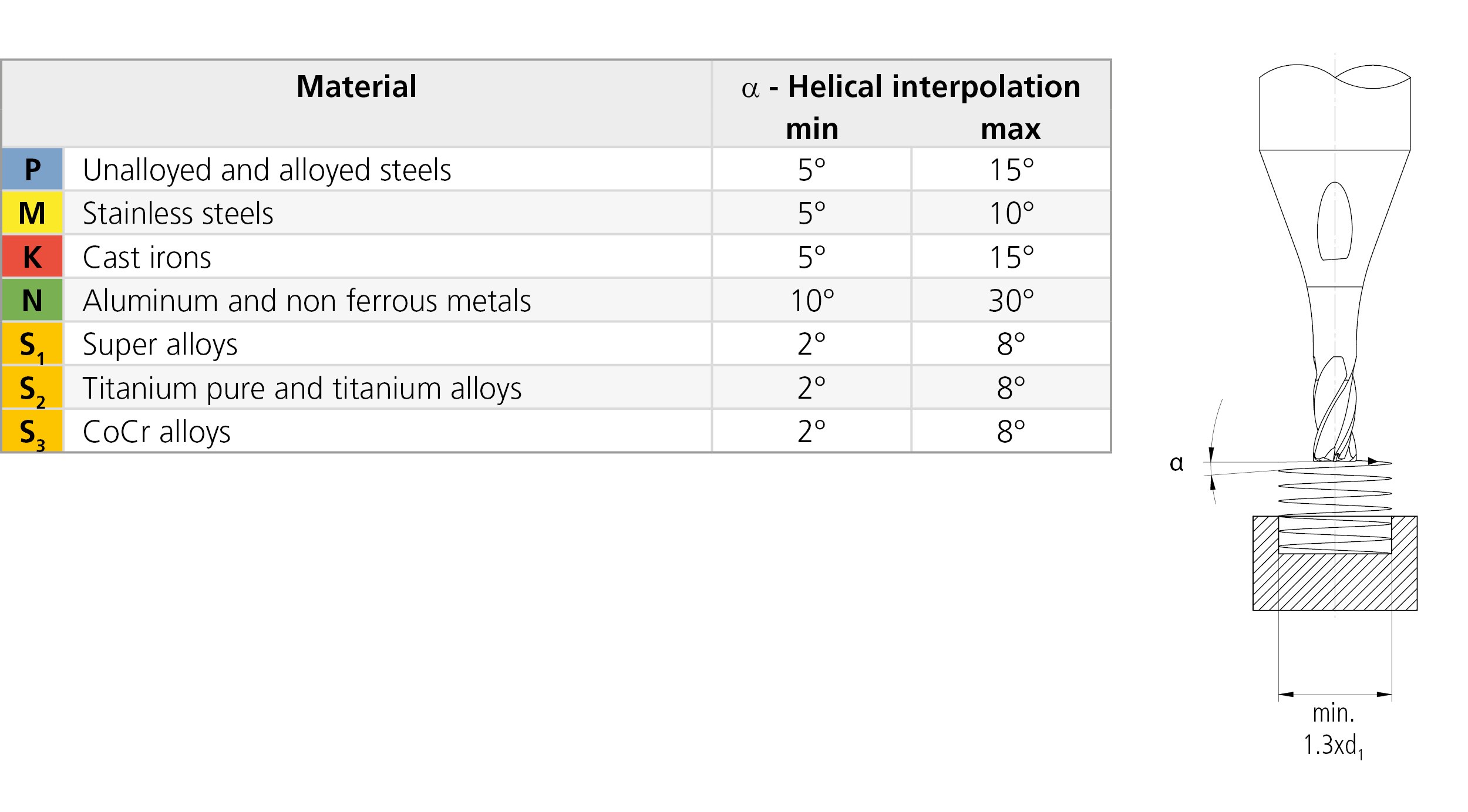

Milling with helical interpolation

Helical interpolation is the best and gentlest way for immersion. Note that the minimum diameter to be produced must be 1.3 x d1. The minimum and maximum helical interpolation angle α depends on the material (see table).

Slot milling

For slot milling, Mikron Tool recommends indirect entry. During milling with direct entry into the material, very thick chips are produced and the milling tool is subject to asymmetrical stress until it is working with its entire diameter in the material. These stresses can affect the service life of cutting edges.

Recommended cutting parameters

vc and fz = as specified in the cutting data table

Note

The recommended ap,max values should not be exceeded.

Tested and approved

Mikron Tool has determined the ideal cutting parameters (ratio of tool life to process reliability) for the use of CrazyMill Cool Micro. Unique cutting data tested at Mikron Tool such as cutting speed vc, feed per tooth fz and cutting depth ap or cutting width ae ensure quick and safe machining.

The cutting data overview for material group, type of material, degree of hardness or tensile strength, material number, DIN and AISI/ASTM/UNS ensure a quick determination of the cutting data to be used.

Packaging

An impact-resistant and user-friendly drill packaging is absolutely necessary for CrazyMill Cool Micro. Mikron Tool offers all tools of the CrazyMill Cool family in a high quality, single package.

Notes or further questions

Please find more information about tool holders, cooling or lubrication under “Additional Info”.

Mikron Tool has an international team of cutting technology experts who are pleased to answer your questions (how to use a drill, tools, machines, tool holders, cooling, machining process…).

Use this link to contact us directly.